Roof and Wall Assembly Testing

Tremco CPG brands work with industry professionals to test building details, insulating glass (IG) units, roof systems and 1- and 2-story wall assemblies for air and water intrusion, thermal performance, fire resistance and structural durability under a variety of environmental stressors.We rigorously test beyond industry standards so building designers, specifiers and owners can be confident their building enclosure systems will perform as intended.

Explore Specific Test Capabilities

Product & System Testing

Our building science initiatives include several laboratory and research facilities where we build mock-ups and test critical components and connections to ensure an air and watertight building enclosure for the lifetime of the structure. We can also assist with active jobsites and existing building testing needs.

Test Wall

To prevent building leaks after construction, our Test Wall enables us to measure air and water infiltration, thermal conductivity and building material compatibility of sample wall assemblies by spraying water and applying positive and negative air pressures to ASTM and AAMA standards and beyond.

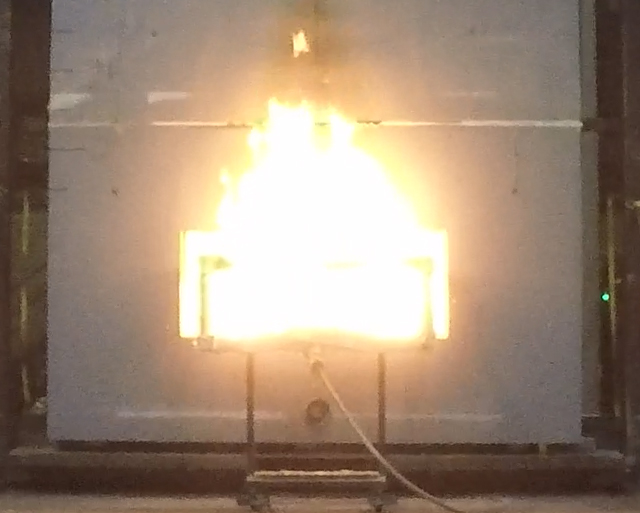

Façade Fire Lab

At our Façade Fire Lab, we can test wall assemblies for fire resistance in accordance with NFPA 285/ISMA, NFPA 268, ASTM E-119/ULCS-101 and CAN/ULC-S1234.

Insulating Glass Lab

To ensure long-lasting Insulating Glass Units (IGUs), we built a state-of-the-art research facility, which allows us to test IGU assembly, evaluate component material performance and conduct forensic analysis of functional IGU systems.

RoofTec Dry Lab

The RoofTec Dry Lab demonstrates the advantages of roof drying and restoration over a roof replacement. Here, we construct built-up roof assemblies, saturate them in water, implement our RoofTec drying system and conduct wind uplift testing to verify roof durability.

Roof System Fire Testing

Our in-house fire laboratory, a certified test facility for UL Solutions*, controls wind speed and flame temperature to test and validate roofs for occupant safety under ASTM E108 and UL 790 criteria.

*Formerly Underwriters Laboratory

Hail Testing

Insurance companies seek to minimize risk by requiring roof systems that resist the impact of hail. Our Very Severe Hail (VSH) testing involves launching simulated hailstones at roofing samples at up to 100 mph to determine impact resistance.